NIPHOS® 966 Nickel-Phosphorus Electrolyte as Alternative to Electroless Nickel

NIPHOS® 966 Nickel-Phosphorus Electrolyte as Alternative to Electroless Nickel

Alternative to electroless nickel

With NIPHOS® nickel-phosphorus alloy layers with high phosphorus content can be plated electrolytically in barrel-, rack- or reel-to-reel lines. Compared to electroless nickel layers containing a high phosphorus content, the electrolytic nickel-phosphorus layers are amorphous, diamagnetic and abrasion and corrosion resistant. The layers can be applied as intermediate layer (prior to e.g. tin, chromium or gold) or as final layer. In comparison to electroless nickel, electrolytic nickel-phosphorus electrolytes are operated at low temperatures.

Nickel-phosphorus electrolytes can be operated with soluble anodes (nickel), insoluble anodes (platinum plated or MMO) or a combination of both. The lifetime is almost unlimited and corresponds to the one of bright nickel electrolytes. NIPHOS® is insensible to contaminations with metallic particles. In contrary to electroless nickel it does not tend to random plating. Also the electrolytes are free from halides and contain, besides nickel, no other heavy metals such as lead or cadmium.

Actions

Advantages

- Cost advantage compared to electroless nickel up to 50%

- High phosphorus content of P > 11 %

- Simple electrolyte maintenance at electrolyte temperatures of 60°C

- Long lifetime of the electrolyte

- Does not contain any halides, sulphur or heavy metals such as lead or cadmium

- Weldable and bondable surface layer

- For rack-, barrel- or reel-to-reel operation

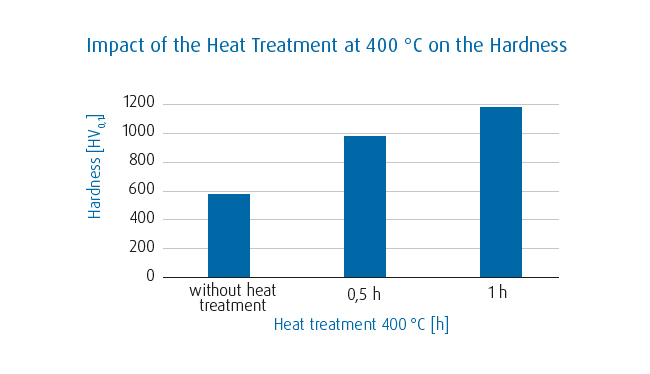

- High hardness (up to 1,200 HV after heat treatment)

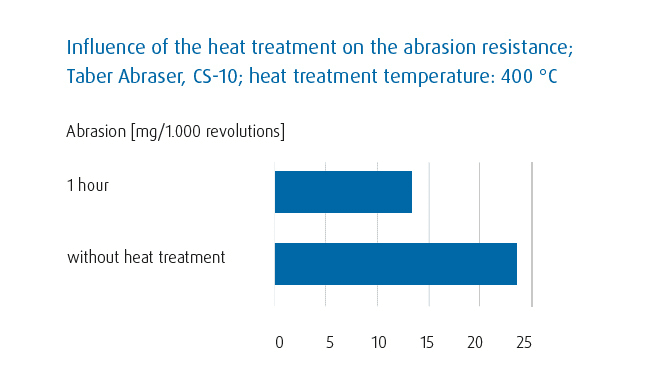

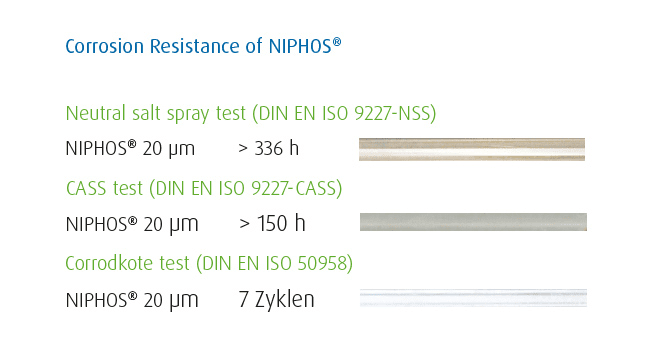

- Very good abrasion and corrosion resistance

- Suitable as final or intermediate layer

Applications

- Diamagnetic coatings of RF connectors

- Intermediate layer prior to gold-plating of connectors

- Electroforming, e.g. of matrices

- Hydraulic, e.g. piston rods

Your contact person